Product Model:

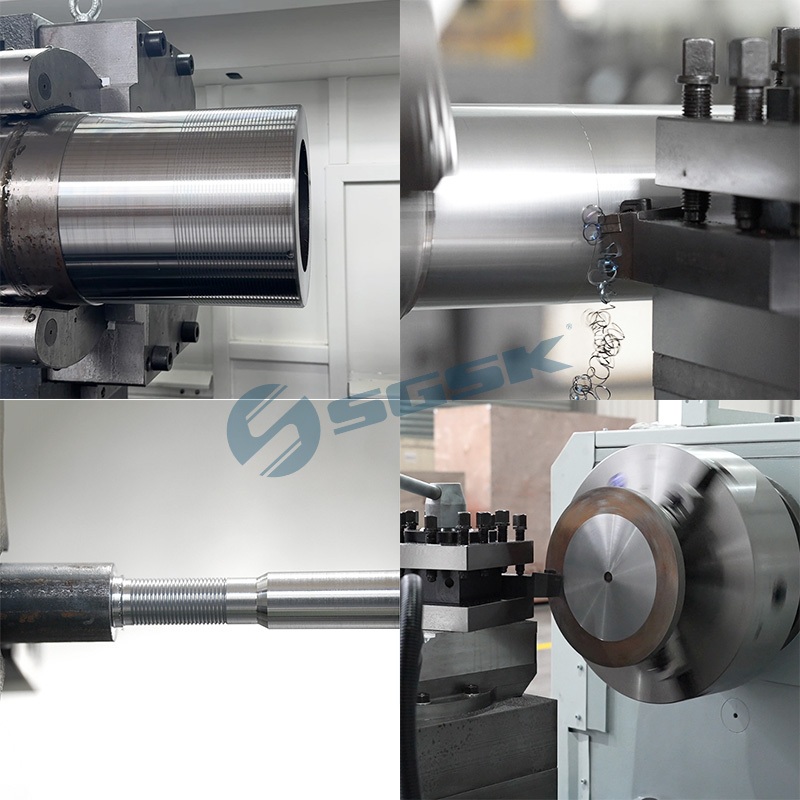

This machine is widely used in processing and manufacture the electric appliance ,instrumentation industry ,automobile ,motorcycle ,fastener bearings ,photographic and film machinery ,hardware tools ,watches ,glasses ,stationery ,motors ,valves and gas pipe and other high precise and complex components .

It is the ideal high efficient equipment in the hardware machining industry .

Features

CNC lathes, with their high precision, high efficiency, high automation, and powerful ability to process complex parts, have become the cornerstone of modern manufacturing.

They cover nearly every area of precision machining, from basic screws and nuts to cutting-edge aerospace components, and are a key force driving the development of industrial automation and intelligent manufacturing.

Application

CNC lathes are widely used in manufacturing industries requiring high-precision rotating parts, primarily in the following areas:

1. Aerospace: Processing high-precision, high-strength, complex alloy parts such as engine blades, rocket nozzles, and landing gear components.

2. Automotive: Manufacturing key components such as engine shafts, pistons, brake discs, and steering gear parts.

3. Mold Manufacturing: Processing cores and cavities for injection and die-casting molds.

4. Medical Devices: Manufacturing parts requiring high biocompatibility and precision, such as artificial joints, surgical instruments, and dental implants.

5. Electronics: Processing cavities, connectors, and precision shafts for communications equipment.

6. General Machinery and Military: Manufacturing standard and custom parts such as drive shafts, lead screws, nuts, valves, and sleeves.

Product Main Technical Parameters

CNC Lathe Machine Features :

1.Big torque ,high precision spindle

2.Hydraulic shift ,easy operate

3.Z axis feed is directly connected which has high transmission accuracy and high positioning accuracy

4.Vertical 4 position electric toolpost with high positioning accuracy

CNC Lathe Machine Main Technical Specifications:

| SPECIFICATIONS | Units | CAK6150 CAK6150B CAK6150C |

| Swing over bed | mm | 500 |

| Swing over cross slide | mm | 280 |

| Distance between centers | mm | 750/1000/1500/2000/3000 |

| Spindle bore | mm | 52,(80 for B),[105 for C] |

| Spindle bore taper | - | MT6,(φ90 1:20 for B),[φ113 1:20 for C] |

| Spindle nose type | - | C6,(D8 for B),[D8 for C] |

| Spindle speed steps | - | Manual 3 steps (Optional: stepless) |

| Spindle speed range | rpm | 21-150,66-500,162-1500 (Optional: 100-1600 ) |

| Turret/tool post | - | Electric 4 position |

| Tool size | mm | 25 x 25 |

| X axis travel | mm | 250 |

| Z axis travel | mm | 750/1000/1500/2000/3000 |

| X axis rapid traverse | mm/min | 6000 |

| Z axis rapid traverse | mm/min | 10000 |

| Tailstock quill diameter | mm | 75 |

| Tailstock quill taper | - | MT5 |

| Tailstock quill travel | mm | 150 |

| Main spindle motor | kw | 7.5 |

| Coolant pump motor | kw | 0.125 |

| Weight for 750 | kg | 2500 |

| Weight for 1000 | kg | 2600 |

| Weight for 1500 | kg | 2700 |

| Weight for 2000 | kg | 3150 |

| Weight for 3000 | kg | 3950 |

| Dimension for 750 | mm | 2550x1650x1750 |

| Dimension for 1000 | mm | 2750x1650x1750 |

| Dimension for 1500 | mm | 3250x1650x1750 |

| Dimension for 2000 | mm | 3700x1650x1750 |

| Dimension for 3000 | mm | 4710x1650x1750 |

| Standard Configuration | Optional Configuration |

Guideway width 400mm VF. 3 steps 3-jaw manual chuck Electric 4 position Manual tailstock | Hydraulic chuck 6/8 Electric turret Hydraulic tailstock Independent spindle |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369