Product Model:

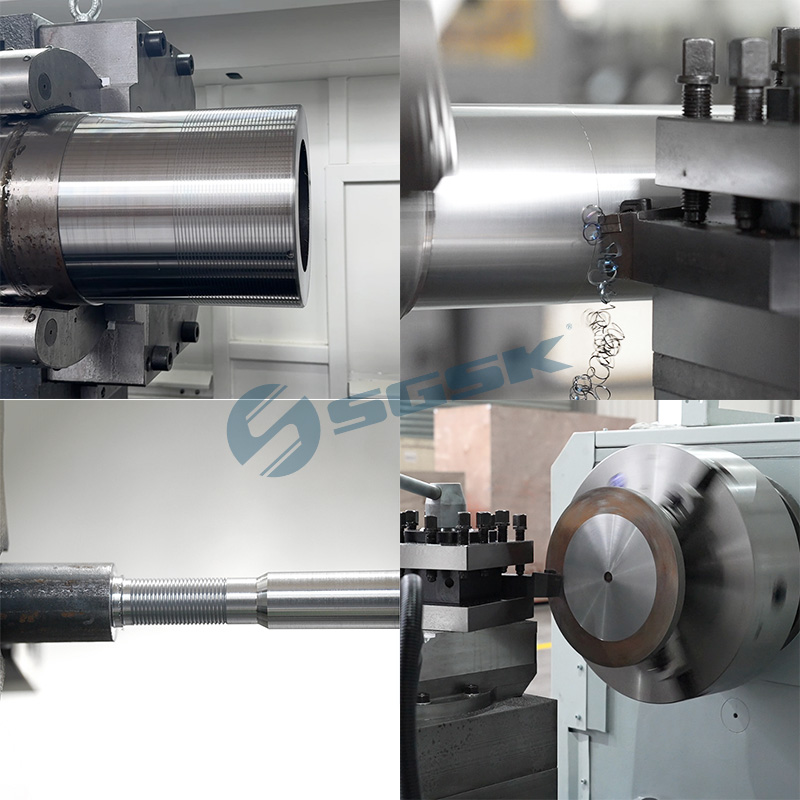

With its high precision, high efficiency, and specialization, the CNC pipe threading lathe has completely solved the problems of sealing, strength, and consistency in pipe thread processing.

It is not only an indispensable "specialized tool" for the oil and gas industries, but also a crucial guarantee for all modern manufacturing industries that rely on high-pressure, sealed pipeline systems.

Features

The CNC pipe threading lathe is a specialized CNC lathe designed specifically for machining precision threads on pipe fittings and joints.

Compared to ordinary CNC lathes or manual pipe threading lathes, it has the following outstanding advantages:

1. High thread machining accuracy and excellent consistency: The CNC system precisely controls the tool movement, completely eliminating the instability of manual operation, and can consistently machine precision threads that meet stringent standards such as API (American Petroleum Institute) and GB/T. This is crucial for ensuring the sealing and tensile strength of pipe connections.

2. Specialization and high efficiency: Dedicated cycle instructions: The CNC system has built-in fixed cycles (such as G92, G76) for pipe threads (such as trapezoidal threads and tapered threads), simplifying programming and greatly improving programming and machining efficiency.

High rigidity structure: The machine bed, spindle, and tool post are all reinforced to withstand greater cutting forces during pipe machining, ensuring stability and accuracy under heavy cutting.

Automated production: It can be easily integrated with automatic feeders, robotic arms, etc., to achieve automatic loading and unloading of pipe fittings, making it particularly suitable for mass production of oil pipes, casings, etc.

3. Strong ability to process complex threads

It can easily process various taper threads, sealing threads, and threads with special profiles (such as domed and flat tops), which are difficult to achieve with conventional equipment.

4. Operational safety and low labor intensity

Fully enclosed or semi-enclosed protective devices effectively prevent splashing of cutting fluid and chips, ensuring operator safety. Automated processing also significantly reduces labor intensity.

Application

CNC pipe threading machines are core equipment for pipe connection system manufacturing, primarily used in the following areas:

1. Oil and Gas Industry (Core Application)

Oil pipes, casing, and drill pipe: Processing API threads (such as API 5B standard) on both ends is its most widespread and important application.

Pipe couplings and fittings: Processing various precision threads for connecting pipes.

Drill collars and kelly: Processing threads on oil drilling tools.

2. Construction Machinery and Hydraulic Systems: Processing high-pressure threads for hydraulic cylinders and hydraulic pipe joints on equipment such as excavators and cranes.

3. Chemical and Energy Equipment: Processing threads for various reactors, pressure vessels, and piping system connectors.

4. Shipbuilding: Processing threads for fuel and lubricating oil pipes for marine engines, as well as joints in various ship piping systems.

Product Main Technical Parameters

CNC Pipe Thread Lathe Machine Introduction:

This series CNC pipe threading lathe is mainly designed for processing internal and external pipe threads including metric, inch, module DP and taper threads, as well as having all the common functions of normal CNC lathe such as processing the inner bore and end face of shafts and disks. This series lathe machine is widely used in industries including petroleum exploiting, minerals mining, chemical piping and geological prospecting, it is high-efficiency equipment in processing and repairing drilling pipe, drilling rod, thread coupling and so on.

CNC Pipe Thread Lathe Machine Features:

Big spindle bore and double chuck to ensure process big diameter pipe

One-piece bed adopts high strength iron to ensure rigidity and precision

Ultrasonic frequency quenched guide-ways ensure good wear-resistance

Carriage and guide way contact surface use Turcite B to maintain accuracy

CNC Pipe Thread Lathe Machine Specification:

| SPECIFICATION | Units | QK1327 | QK1332 |

| Swing over bed | mm | 1000 | 1000 |

| Swing over cross slide | mm | 610 | 610 |

| Distance between centers | mm | 1500/3000 | 1500/3000 |

| Pipe threading range | mm | 130-270 | 190-320 |

| Guideway width | mm | 755 | 755 |

| Max. load capacity | T | 6 | 6 |

| Spindle bore | mm | 280 | 330 |

| Spindle speed steps | - | VF. 4 steps | VF. 3 steps |

| Spindle speed range | rpm | 10-320 | 10-280 |

| Chuck | mm | φ800 4-jaw manual | φ7804-jaw electric |

| Turret/tool post | - | 4 position eletric tool post/NC turret 4 position | |

| Tool shank size | mm | 40 x 40 | 40 x 40 |

| X axis travel | mm | 520 | 520 |

| Z axis travel | mm | 1250/2750 | 1250/2750 |

| X axis rapid traverse | mm/min | 4000 | 4000 |

| Z axis rapid traverse | mm/min | 4000 | 4000 |

| Tailstock quill diameter | mm | φ160 | φ160 |

| Tailstock quill taper | - | MT6 | MT6 |

| Tailstock quill travel | mm | 300 | 300 |

| Main spindle motor | kW | 22 | 22 |

| Coolant pump motor | kW | 0.125 | 0.125 |

| Weight for 1500 | kg | 10500 | 11500 |

| Weight for 3000 | kg | 12200 | 12500 |

| Dimension for 1500 | mm | 4950x2050x2050 | 5000x2080x2080 |

| Dimension for 3000 | mm | 6450x2050x2050 | 6500x2080x2080 |

| STANDARD ACCESSORIES | OPTIONAL ACCESSORIES |

CNC turret 4 position 3-jaw manual, Tailstock manual, automatic lubrication, coolant pump, semi-shield | Fanuc or other brand CNC controller, quick change tool post, hydraulic turret or power turret, pneumatic chuck, hydraulic tailstock, pneumatic position limiter, tool setting arm, full-shield |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369