Product Model:

Heavy-duty CNC lathes are specialized CNC machine tools designed for machining large, extra-heavy, and complex rotating parts. Compared to conventional CNC lathes, they offer a significant improvement in size, load capacity, drive power, and overall rigidity. They can typically process diameters of several meters, lengths of more than ten or even dozens of meters, and load capacities of tens or even hundreds of tons.

Features

Heavy-duty CNC lathes are a symbol of China's heavy industrial strength. They address the challenge of producing large, basic components with precision and accuracy. They offer more than just a simple increase in size; they represent a comprehensive upgrade in rigidity, power, stability, and control technology. They are the cornerstone equipment supporting the development of the large-scale equipment manufacturing industry.

In addition to inheriting the high precision and efficiency of conventional CNC lathes, heavy-duty CNC lathes, due to their "heavy-duty" design, offer the following outstanding features:

1. Immense Structural Rigidity and Stability

Bed Structure: Crafted from high-quality cast iron or welded steel, key components like the bed and base are reinforced with ribs, ensuring exceptional strength and stability despite the immense workpiece and cutting forces, fundamentally guaranteeing machining accuracy.

2. Spindle System: Equipped with an oversized, highly rigid spindle box and heavy-duty spindle bearings, they provide exceptional torsional rigidity and load-bearing capacity.

3. Powerful Drive Power and Torque

Equipped with a high-power spindle motor and servo motor, they deliver impressive cutting torque. This enables them to perform heavy-duty roughing operations with high stock removal on large forgings and castings, efficiently removing excess stock.

4. Excellent Load-Bearing Capacity: Utilizing a high-strength chuck, steady rest, and tailstock, along with specially reinforced bed guideways, they are capable of stably supporting and rotating workpieces weighing tens of tons. 5. Ability to Meet Special Machining Requirements

Vibration Resistance: Specially designed to suppress vibrations that may occur during heavy cutting, ensuring excellent surface quality during both roughing and finishing.

6. Thermal Deformation Control: Due to the long machining cycles that generate significant heat, heavy-duty CNC lathes are typically equipped with comprehensive cooling and thermal compensation systems to minimize the impact of thermal deformation on precision.

7. High Level of Automation and Intelligence

Modern heavy-duty CNC lathes are often equipped with automatic tool magazines, in-machine tool setters, workpiece measurement systems, and even automated loading and unloading robots to reduce worker workload and improve safety when machining extremely large workpieces.

Application

Heavy-duty CNC lathes are indispensable "machine tools" in the manufacturing of major technical equipment, primarily used in the following applications:

1. Energy Equipment Manufacturing

Hydropower: turbine main shafts, rotors, and mirror plates.

Thermal/Nuclear Power: Turning of steam turbine rotors, generator main shafts, and the inner wall of nuclear reactor pressure vessels.

Wind Power: Turning of large wind turbine main shafts and gearbox components.

2. Shipbuilding

Marine diesel engines: Large crankshafts, camshafts, and cylinder liners.

Propulsion systems: Propeller shafts and rudder stocks.

3. Metallurgical and Mining Equipment: Rolling mill rollers, large gear blanks, and drive shafts for mining machinery.

4. Aerospace and Defense: Rocket engine casings, large rings, landing gear outer barrels, tank gun barrels, etc.

5. Large Construction Machinery: Excavator slewing bearings and hydraulic cylinders, etc.

Product Main Technical Parameters

Heavy Duty CNC Lathe Machine Main Features and Uses:

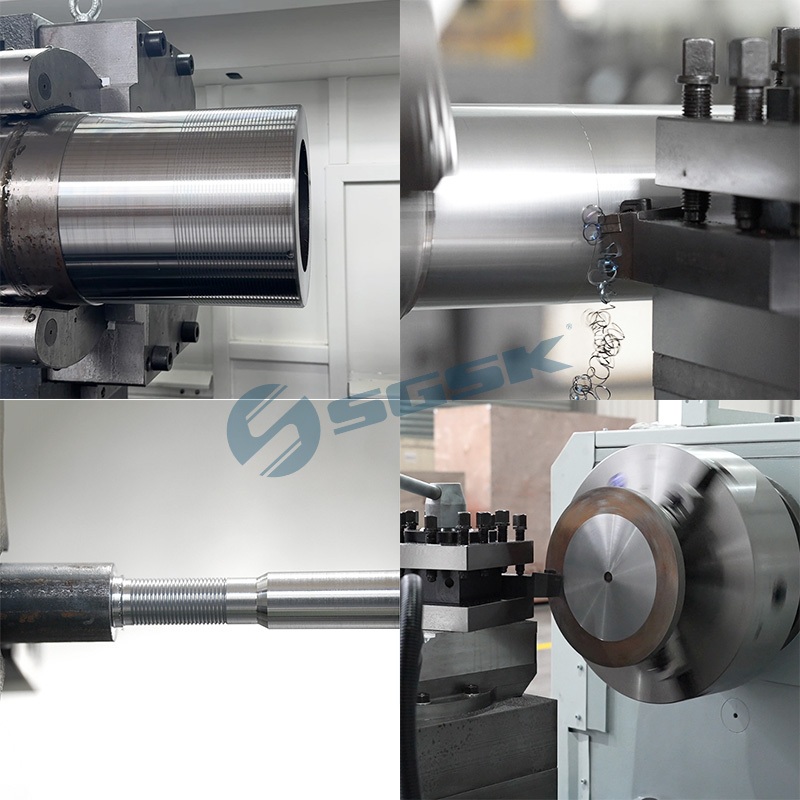

This machine can undertake a variety of turning workpiece, it can turning the various parts of the outer circle, inner hole, end and metric thread, Whitworth, module thread and pitch diameter of the thread forming surface; in addition, you can also meet drilling, every hole, sets and other materials process requirements. It can also be used in hard cutting tool for powerful cutting, processing a variety of ferrous and non-ferrous metals.

The width of the side wall of the double bed ribs, inner ribs with box and diagonal reinforcement integral bed structure, high integral rigidity.

Heavy Duty CNC Lathe Machine Main Technical Specification:

| SPECIFICATIONS | Units | CK61180G | CK61200G |

| Swing over bed | mm | 1900 | 2100 |

| Swing over cross slice | mm | 1450 | 1650 |

| Distance between centers | mm | 3000-20000 | 3000-20000 |

| Guideway width | mm | 1100 | 1100 |

| Max.load capacity | T | 10/15(G/I) | 10/15(G/I) |

| Spindle bore | mm | 100 /130(G/I) | 100 /130(G/I) |

| Spindle bore taper | - | 公制Metric120 /公制Metric140(G/I) | 公制Metric120 /公制Metric140(G/I) |

| Spindle nose type | - | 1:30加长主轴头 /Extended spindle head | 1:30加长主轴头 /Extended spindle head |

| Spindle speed steps | - | 4档变频 / VF. 4steps | 4档变频 / VF. 4steps |

| Spindle speed range | rpm | 10-300/2-200(G/I) | 10-300/2-200(G/I) |

| Chuck | mm | φ1600手动四爪 /φ1600 4-jaw manual | φ1600手动四爪 /φ1600 4-jaw manual |

| Turret/tool post | - | 4工位电动刀架 /Electric 4 position | 4工位电动刀架 /Electric 4 position |

| Tool size | mm | 50*50 | 50*50 |

| X axis travel | mm | 850 | 850 |

| Z axis travel | mm | 2750-19750 | 2750-19750 |

| X axis rapid traverse | mm/min | 4000 | 4000 |

| Z axis raoid traverse | mm/min | 6000 | 6000 |

| Tailstock quill diameter | mm | φ260 | φ260 |

| Teilstock quill taper | 公制80/Metric 80 | 公制80/Metric 80 | |

| Taistock quill travel | mm | 300 | 300 |

| Main spindle motor | kW | 37 | 37 |

| Coolant pump motor | kW | 0.25 | 0.25 |

| Overall dimension(W*H) | mm | 2300*2500 | 2300*2600 |

| Overall dimension(L) | mm | 7200-24200 | 7200-24200 |

| Net weight(5m) | t | 23 | 24 |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369