Product Model:

CNC milling machining centers play a crucial role in manufacturing, especially when handling large or complex workpieces.

Their core value lies in their superior stability, extremely high machining accuracy, and powerful versatility.

Features

With its outstanding performance of "heavy load, high precision, high efficiency, and composite capabilities", the gantry CNC machining center has become the ultimate solution for manufacturing large, complex, and high value-added parts, and is one of the important indicators for measuring the level of a country's high-end equipment manufacturing industry.

1. Exceptional Rigidity and Stability:

Thanks to its integrated gantry frame structure, the machine tool body possesses exceptional vibration resistance and load-bearing capacity. This enables it to perform heavy cutting with large cutting volumes while maintaining excellent precision stability during prolonged continuous machining.

2. Superior Machining Accuracy:

The combination of high-precision guideways, lead screws, and an advanced CNC system achieves micron-level positioning accuracy. This is crucial for ensuring the overall dimensional and geometric tolerances of large workpieces (such as aircraft structural components and precision molds).

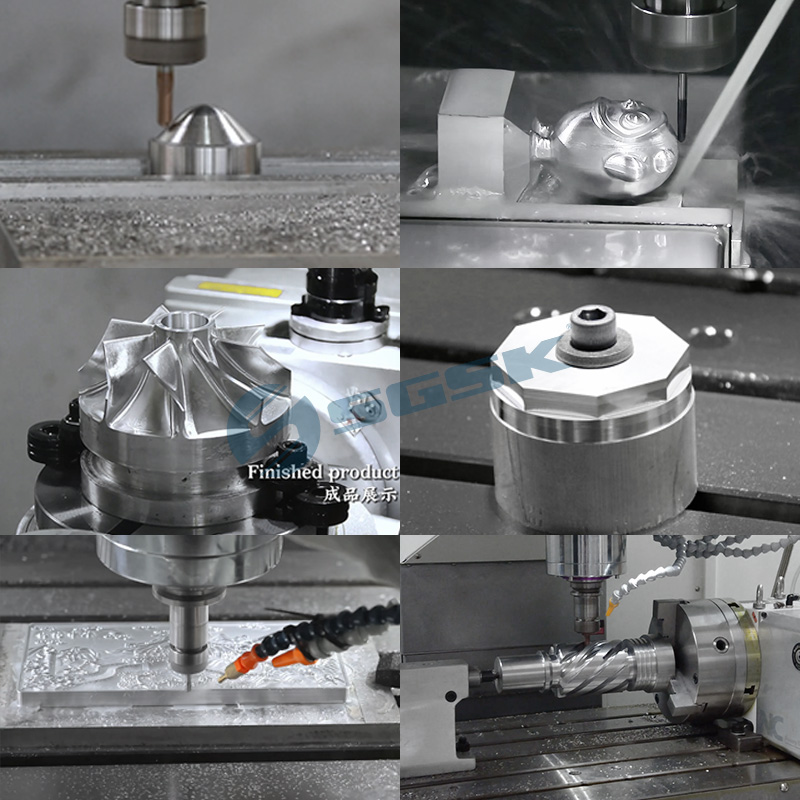

3. Powerful Multifunctionality and Composite Machining Capabilities:

As a "machining center," it comes standard with a large-capacity automatic tool changer, enabling it to complete multiple processes such as milling, drilling, boring, and tapping in a single operation. Through multi-axis linkage, it can also machine complex spatial surfaces and irregularly shaped holes.

4. A Natural Machining Platform for Large Workpieces:

The gantry structure provides ample machining space, allowing the worktable to easily accommodate and move heavy, oversized workpieces—a capability unmatched by other machine tool structures.

5. Highly efficient automated production:

The automatic tool changer and optional automatic pallet exchange device enable all processes to be completed after a workpiece is clamped once, greatly reducing auxiliary time and making it an ideal platform for flexible manufacturing and automated production.

Application

Leveraging their unique advantages, gantry machining centers are widely used in the following high-end manufacturing fields with stringent requirements for size, precision, and complexity:

1. Aerospace Industry:

Core equipment for machining large aluminum alloy and titanium alloy structural components such as aircraft wing spars, fuselage frames, rocket bodies, and engine support mounts.

2. Mold Manufacturing Industry:

Widely used for machining cavities and three-dimensional surfaces in automotive body panel molds, large injection molds, and die-casting molds.

3. Energy and Heavy Machinery:

Used to manufacture key components for wind turbine generators (such as gearboxes and bearing housings), turbine runners, steam turbine cylinder blocks, and the beds and columns of heavy-duty machine tools.

4. Automotive and Rail Transportation:

Machining molds for automotive body panels, die-casting molds for complete vehicles, and large structural components for high-speed rail and subway vehicles.

5. Shipbuilding and Military Manufacturing:

Used to manufacture ship engine components, large propellers, and frames and shells for various military equipment.

Product Main Technical Parameters

| SPECIFICATIONS | Units | GMC3022 | GMC4022 | GMC5022 |

| Table size(W*L) | mm | 2000*3000 | 2000*4000 | 2000*5000 |

| X axis travel | mm | 3000 | 4000 | 5000 |

| Y axis travel | mm | 2200(副行程Secondary stroke2700) | ||

| Z axis travel | mm | 1000 | 1000 | 1000 |

| Gantry width | mm | 2300 | 2300 | 2300 |

| Gantry passing height | mm | 1400 | 1400 | 1400 |

| Table load | t | 10 | 12 | 14 |

| Distance between spindle nose and table surface | mm | 280~1280 | 280~1280 | 280~1280 |

| T slot(number-width*pitch) | - | 9-28*200 | 9-28*200 | 9-28*200 |

| Spindle taper | - | BT50/200 | BT50/200 | BT50/200 |

| Spindle speed | r/min | 6000 | 6000 | 6000 |

| Rapid traverse speed | m/min | 12 | 12 | 12 |

| Cutting feed speed | m/min | 8 | 8 | 8 |

| Main motor power | kw | 18.5 | 18.5 | 18.5 |

| Tool magazine | 圆盘Arm 30 | 圆盘Arm 30 | 圆盘Arm 30 | |

| Positioning accuracy | mm | X/Y ±0.0075 Z ±0.015 | X/Y ±0.0075 Z ±0.015 | X/Y ±0.0075 Z ±0.015 |

| Repeat positioning accuracy | mm | ±0.005 | ±0.005 | ±0.005 |

| Overall dimension(L*W*H) | mm | 10750*5940*5100 | 12750*5940*510039 | 14750*5940*510039 |

| Machine weight(about) | t | 39 | 43 | 48 |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369