Product Model:

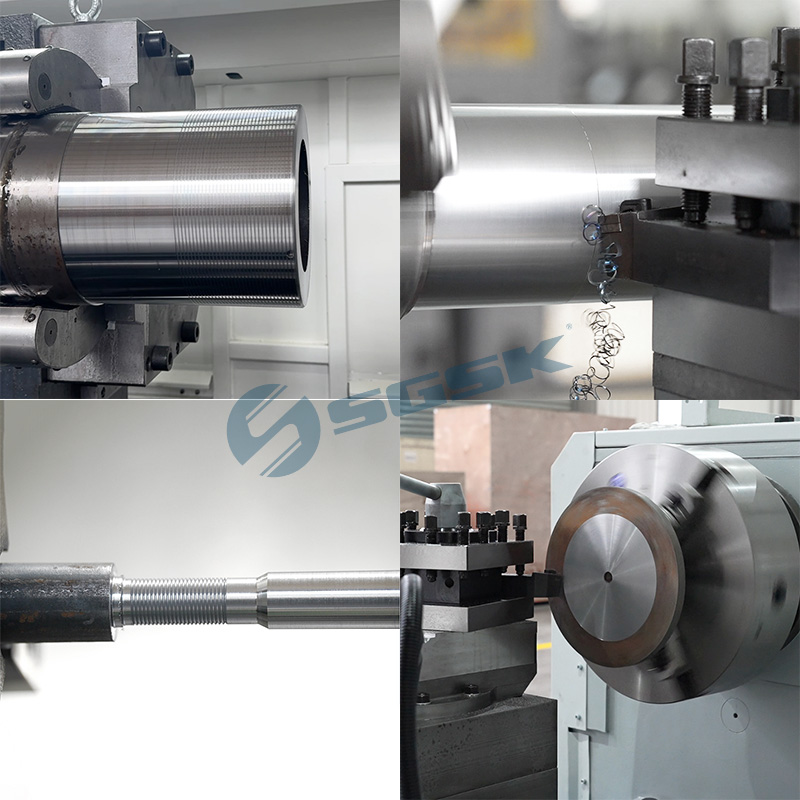

With its outstanding features of "high load-bearing capacity, easy clamping, smooth chip removal, and high precision",

the CNC vertical lathe occupies an irreplaceable core position in the machining of large disc-shaped, ring-shaped, and short shaft-shaped parts, and is one of the cornerstone equipment of modern heavy equipment manufacturing industry.

Features

The spindle of the CNC vertical lathe is perpendicular to the horizontal plane, and the workpiece is clamped on the horizontal worktable.

This unique layout brings several key advantages:

1.Superior load-bearing capacity and stability:

Its vertical structure allows the workpiece's weight to act directly on the robust worktable base, providing an ideal machining platform for heavy, large disc-shaped, and box-shaped workpieces. Stable workpiece clamping effectively resists cutting forces, ensuring rigidity and smoothness during machining.

2.Convenient workpiece clamping and alignment:

Placing the workpiece on the horizontal worktable is like placing it on a table, greatly simplifying the lifting, positioning, and alignment processes. Operators can easily observe and measure, significantly reducing labor intensity and improving clamping efficiency.

3.Efficient chip removal and excellent cutting fluid management:

Under gravity, hot chips and cutting fluid naturally and smoothly fall into the chip chute and are quickly carried away. This feature effectively avoids damage to the workpiece and tool caused by chip accumulation in the machining area, while facilitating rapid heat dissipation, ensuring machining accuracy and tool life.

4.High Precision and Consistency:

Thanks to its stable structure and high-rigidity spindle system, CNC vertical lathes achieve excellent turning accuracy and repeatability. Its layout effectively reduces workpiece deformation during machining, making it particularly suitable for the precision machining of thin-walled ring-shaped parts.

5.Easy to Automate:

The horizontal worktable provides a natural advantage for integrating automated loading and unloading systems (such as robots or articulated arms), making it ideal for building flexible manufacturing cells (FMC) and automated production lines, enabling efficient, continuous "lights-out" production.

Application

CNC vertical lathes are specifically designed for machining large, heavy, or specifically shaped parts and are key equipment in the following industries:

1.Heavy Machinery and Energy Equipment:

Used for machining wind turbine main shafts, gearbox end covers, turbine blade flanges, upper and lower crowns, and end covers and housings of large electric motors.

2.Automotive and Rail Transportation:

Used for manufacturing automobile wheel hubs, brake drums (brake discs), flywheels, and disc-shaped parts for train wheels and locomotive drive systems.

3.Aerospace and Military:

Used for machining large rotating components such as aircraft landing gear ring structures, engine casings, and missile casings.

4.General Large Equipment Manufacturing:

The preferred equipment for producing large gearbox housings, valve flanges, large bearing housings, and various large equipment end covers.

Product Main Technical Parameters

| Specifications | Units | VTC600 |

| Maximum rotating diameter of machine tool | mm | 600 |

| Max turning diameter | mm | 500 |

| Tool rest vertical movement length | mm | 400 |

| Tool rest horizontal movement length | mm | -50-300mm |

| Spindle speed range | rpm | 50-1000rpm |

| Spindle torque | NM | 105 |

| Cutting feed rate | mm/min | 0.1-1000 |

| X Axis rapid feed rate | mm/min | 1500 |

| X Axis rapid feed rate | mm/min | 1200 |

| Tool rest structure | 8 station hydraulic Turret | |

| Tool section | mm | 25x25mm |

| Diameter of hydraulic chuck | mm | 305 |

| Main motor power | kw | 5.5/7.5 |

| positioning accuracy | mm | 0.006 |

| Repeated positioning accuracy | mm | 0.004 |

| Net weight | kg | 3800 |

| Machine tool overall dimension | mm | 2250×1960×2300 |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369