Product Model:

The slant bed CNC lathe with a 12-station power turret has achieved a leap from single-process machining to complete part manufacturing through the technologies of "milling-turning" and "one-time clamping". It is the core equipment for the development of modern manufacturing towards high efficiency, high precision and high flexibility.

Features

Machine tools with this configuration (often called mill-turn centers) are powerful tools for high-end manufacturing, and their core advantages lie in "composite, efficient, and precise".

1. Highly Concentrated Processes, All Machining Completed in a Single Setup

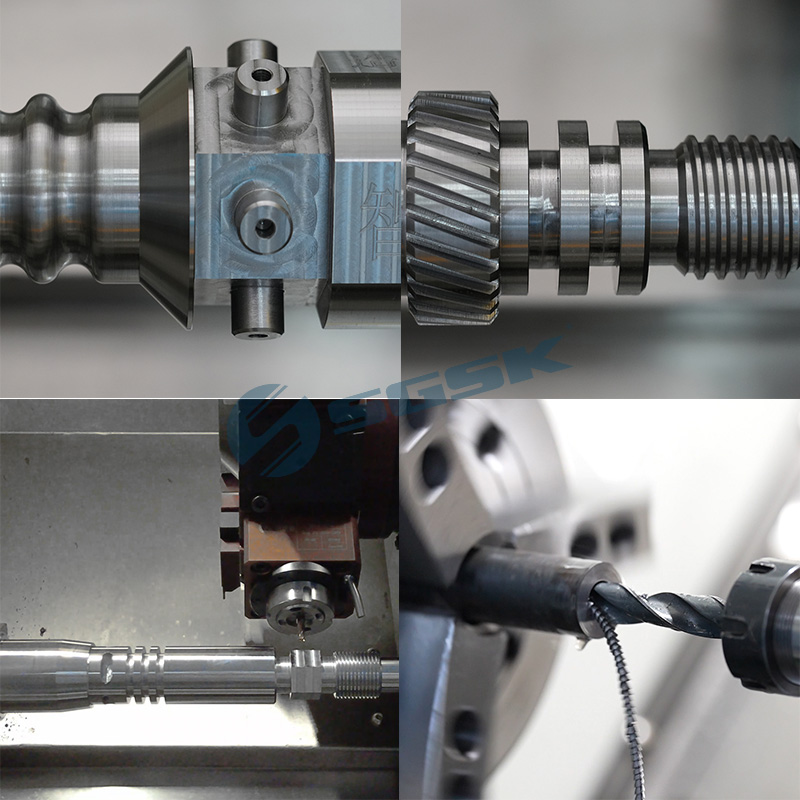

The biggest advantage lies in integrating turning, milling, drilling, and tapping processes onto a single machine tool.

The 12-station power turret provides ample tool capacity, allowing simultaneous mounting of turning tools and rotary power tools.

Result: This avoids parts being moved between multiple machine tools and repeatedly clamped, significantly shortening machining time and fundamentally eliminating accuracy errors caused by secondary clamping.

2. Extremely High Machining Accuracy and Consistency

The slant bed structure provides extremely high rigidity and stability, ensuring accuracy is maintained even under heavy cutting.

The "single setup" strategy guarantees a unified machining datum, allowing for perfect control of the form and position tolerances (such as concentricity and perpendicularity) of complex parts.

3. Leapfrog Improvement in Machining Efficiency

The power turret supports the linkage between milling power and the turning spindle under CNC system control, enabling the machining of complex features such as eccentric grooves, planes, and cams.

In conjunction with a high-performance CNC system, high-speed, high-precision continuous machining can be achieved, making it particularly suitable for small-batch, multi-variety production.

4. An Ideal Platform for Automated Production: The slant bed facilitates chip removal and integration with automated devices (such as robotic arms and feeders).

Powerful turning and milling capabilities enable the complete machining cycle of a single part to be run unmanned on the same machine, making it a core piece of equipment for building "lights-out factories" and flexible manufacturing cells (FMC).

Application

1. Aerospace: Engine blade tenons, aircraft hydraulic fittings, complex structural components for UAVs.

2. Medical Devices: Artificial joints (hip/knee joints), surgical instruments, bone screws, titanium alloy implants.

3. Automotive Industry: Turbocharger rotors, gearbox gear shafts, brake system components, steering knuckles.

4. Precision Hydraulics and Transmission: Complex pump bodies, valve blocks, servo motor housings, gearbox gears.

5. High Value-Added Parts: Any precision part requiring simultaneous turning of the outer diameter and milling of the end face/side surface.

Product Main Technical Parameters

| SPECIFICATIONS | Units | TCK56Y | TCK63Y | TCK80Y |

| Swing over bed | mm | 560 | 720 | 800 |

| Max. workpiece length | mm | 500/1000 | 1000/1500/2000/3000 | 1000/1500/2000/3000 |

| Max. cutting diameter | mm | 310 | 500 | 600 |

| Spindle bore | mm | 65 | 80 | 80 |

| Spindle nose type | - | A2-6(Opt.A2-8) | A2-11(A2-8) | A2-11(A2-8) |

| Spindle speed steps | - | Stepless | Stepless | Stepless |

| Spindle speed range | rpm | 50-4500 | 2000(3000) | 2000(3000) |

| Chuck | - | 8'' Hollow hydraulic chuck (Opt. 10'') | 12'' Hollow hydraulic chuck | 12'' Hollow hydraulic chuck |

| X axis travel | mm | 200 | 300 | 350 |

| Y axis travel | mm | ±50 | ±50 | ±50 |

| Z axis travel | mm | 450/900 | 900/1400/1900/2900 | 900/1400/1900/2900 |

| X axis rapid traverse | mm/min | 30 | 12 | 12 |

| Y axis rapid traverse | mm/min | 12 | 12 | 12 |

| Z axis rapid traverse | mm/min | 30 | 16 | 16 |

| Main motor power | kw | 11~15 | 15/18.5(Opt.37) | 18.5(Opt.37) |

| Turret type | 12 Station power turret | |||

| Turret Model | BMT45-ER25 | BMT55-ER32 | BMT65-ER32 | |

| Tailstock quill taper | - | MT4(Opt.MT5) | MT5 | MT6 |

| Tailstock base travel | mm | 400/900 | 900/1400/1900/2900 | 900/1400/1900/2900 |

| Guide rail type | - | Slant bed linear rail | Slant bed linear rail/Hard guideway | |

| Machine weight | kg | 4800/6500 | 6000/7000/8000/10000 | 7000/8000/9000/11000 |

Navigation

Tel.: +86 632 5083 879

Mob.: +86 151 6326 5369

Wechat: +86 151 6326 5369

E-mail: info@gskequipment.com

WhatsApp: +86 151 6326 5369